ICE

by F.H. Forbes

from Scribner's Monthly Magazine

Volume 10, Number 9, August 1875

Page 2

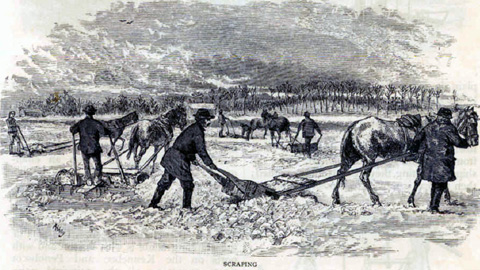

A space on the pond, say six hundred feet in width, is marked out and the snow is scraped from either side toward the center, forming what is called " the dump." Some seasons these dumps will rise to a great height, and then, through their immense weight, sink to a level. The process of scraping the snow into " dumps " is not only expensive, but wastes a great deal of ice, as only that cleared off can be cut. When the ice is twelve inches thick it will yield about a thousand tons to the acre, but so much is wasted by scraping snow, high winds, and various other causes, that it is only in exceptionally "good years" that more than half the average of a pond can be cut and stored.

Scraping the Pond (Picture from article)

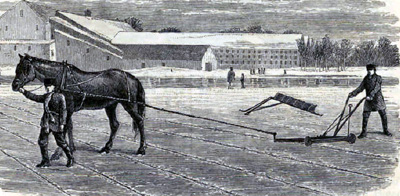

After the snow is scraped off, the lining of the pond, so called, begins. This is done by taking two sights as in common railroad engineering. The targets are set, represent-ing the line between two supposed points, say A and B. A straight edge is then run by means of a common plank between the points A and B, then striking from the angle B, it runs at right angles with the line A. Only two lines are necessary, one from A to B, and the other from B to an indefinite point.

The liner proceeds with a double instrument, or what is called a " guide and marker ;" the guide is a smooth-edged blade that runs in the groove made by the square edge; the marker is a part of the same instrument and runs over the grooved lines laid out with the cutter. As soon as the machine reaches the objective point, it is turned over by an ingenious arrangement, so that returning, the guide runs in the freshly cut groove, and the marker cuts another groove forty-four inches distant. In this way the machine goes over the whole field, running one way, the last groove it cuts forming the boundary of the second side; then, commencing on this boundary line, it runs at right angles with the first, and goes over the entire field, cutting the ice into blocks of the required dimensions. The marker cuts a groove two inches in depth.

Marking the Pond

(Picture form article)

Following the marker come the cutters or plows (shown in background resting upside dowwn) with sharp teeth measuring from two inches in length to ten or twelve, and used according to the thickness of the ice. Then comes the snow-ice plane, which shaves off the porous or snow ice, it first being determined by auger-boring how many inches of snow ice there are. The ice is now ready for gathering.

Planing the Ice

(from original article)

It is broken off into broad rafts, then sawed into lesser ones, then barred off in sections and floated into the canal. The calking operation consists in filling the groove lines or interstices with ice chips to prevent the water from entering and freezing; this is only necessary in very cold weather. The rafts or sheets of cakes are generally thirty cakes long by twelve wide, frequently longer. The ends have to be sawed, but every twelfth groove running lengthwise of the raft or sheet is cut deeper than the other, so that one or two men can, with one motion of the bar, separate it into strips ready for the elevator canal.

Sawing, Caulking and Barring Off

(from original article)

As the ice enters upon the van it is cut into single cakes of forty-four inches square. The process of elevating the ice has been reduced to almost scientific perfection. It is done by means of an endless chain fitted with buckets, and the hoisting power is a steam-engine. The ice-houses contain from three to five vaults or bins, corresponding to the several stories in a warehouse. A single range of buildings will contain five or more. The elevator is arranged so that one flat or story containing these five bins or vaults can be filled simultaneously; that is, as the ice leaves the elevator and is passed off on the wooden tramway of the platform, a man stands at the entrance of each vault to turn the cakes of ice in, the first cake from the elevator going to the farthest opening, and then in regular rotation till the first or lower flat in the range is filled. When the blocks are taken from the houses and loaded on board cars for shipment, they are reduced to twenty-two inches by a similar process of grooving and burring.

None but the most experienced workmen are employed in storing the ice, as this requires a quick eye, a steady hand, and good judgment.

As each flat or story is completed, the openings at either end are securely and tightly closed, and when the whole building is filled up to the bed-plate, the space between that and the hip of the roof is filled with hay, thus providing a sure protection against waste by shrinkage, which seldom exceeds one foot during the season.